Description

Specifically Built for Large Sample Wafer Inspection

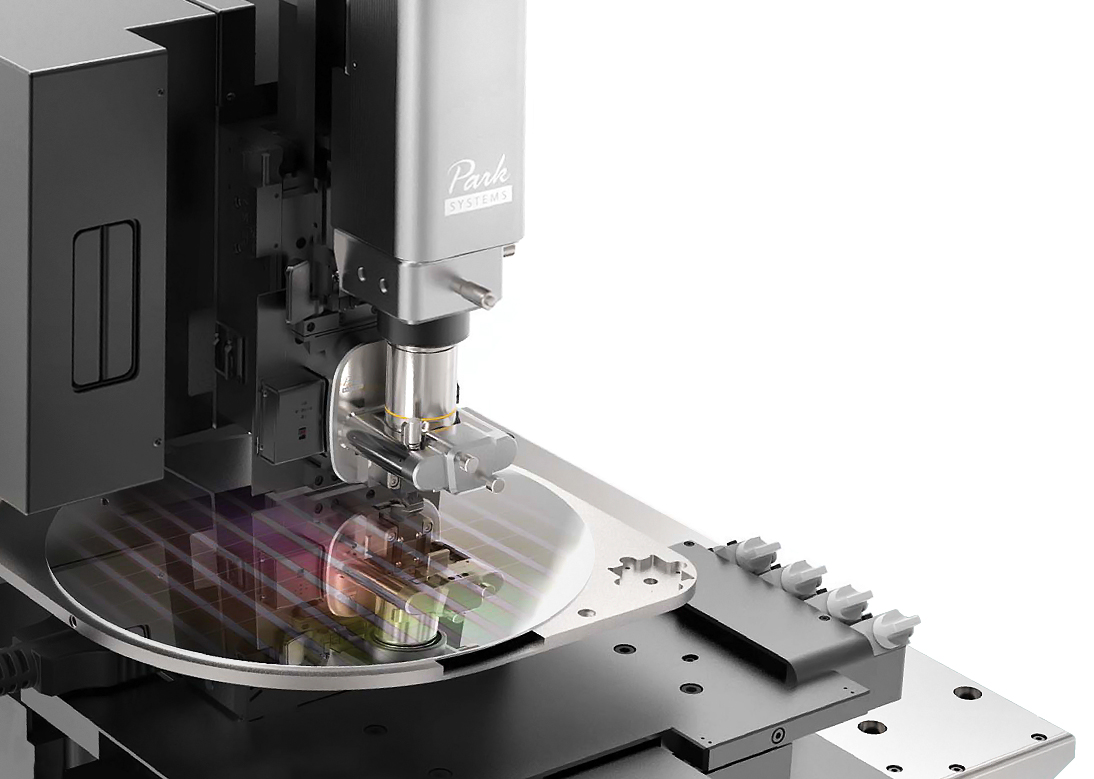

The NX20 300 mm was designed from the ground up to allow for optimal measurements of large samples. The entire 300 mm wafer area can be analyzed for low-noise AFM measurements. This opens up a whole new scope of measurement automation, allowing engineers to work faster, more simply, and with greater precision.

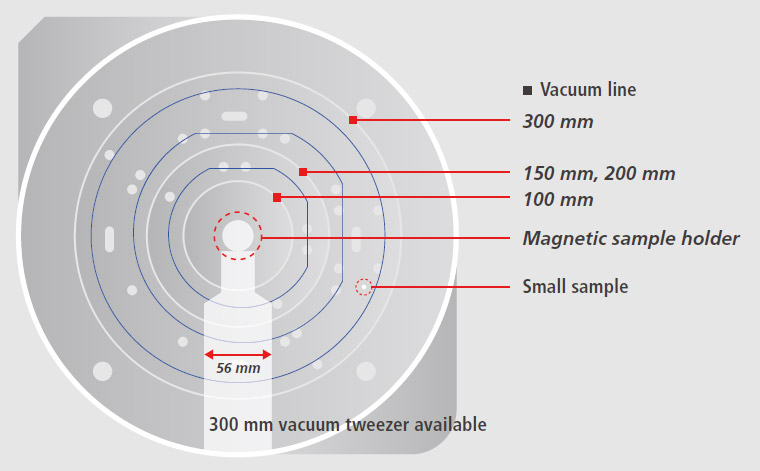

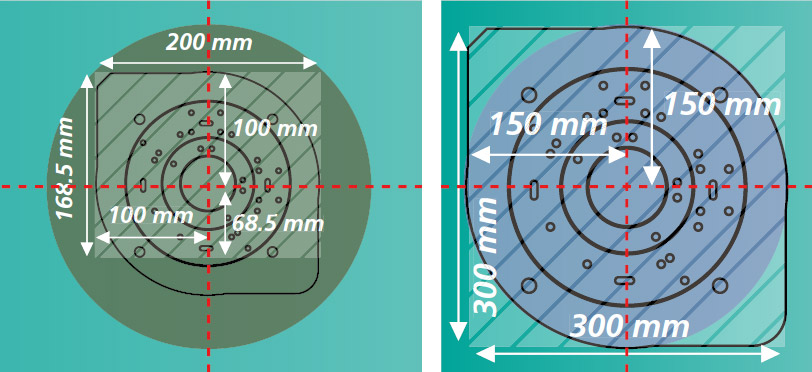

Flexible 300 mm Sample Chuck

The Park NX20 300 mm’s vacuum chuck supports a wide range of wafer sizes, shapes, and types allowing users to accurately scan practically any sample.

300 mm XY stage

The motorized 300 mm XY stage allows users to move the AFM measuring position within the entire 300 mm area.

Proven NX20 Performance with a 300 mm sample stage

The NX20 is already the best choice for FA, QA, and QC engineers that need its unparalleled ease of use and automation without compromising on accuracy. With its enlarged platform that supports a 300mm motorized XY stage, the NX20 300 mm takes this a step further, allowing users to inspect larger samples easily and with extremely high accuracy.

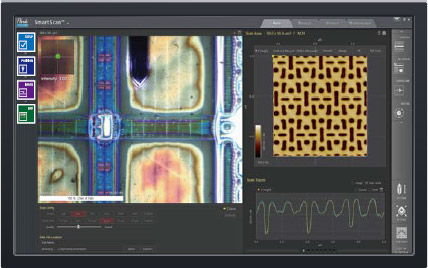

Park SmartScan™ makes getting accurate measurements simple

The Park NX20 is equipped with our SmartScan OS, making it one of the easiest-to-use AFMs on the market. With an intuitive but extremely powerful interface, even untrained users can quickly scan a large sample without supervision. This lets senior engineers focus their experience on solving bigger problems and developing better solutions.

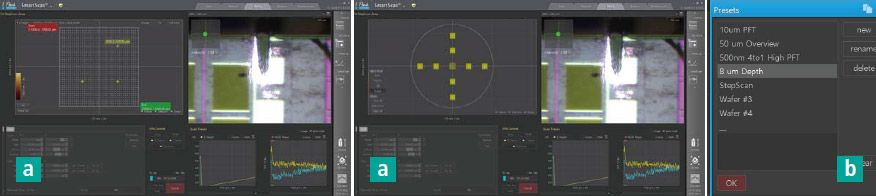

aScan multiple sites on the entire 300 mm wafer

SmartScan’s program mode allows users to take automated sequential site measurements, compare surface morphologies, height, surface roughness from site-to-site and sample-to-sample using grid and wafer-based modes. This can greatly improve user convenience and productivity when scanning large samples.

bPowerful recipe creation

Our simple recipe creation process allows engineers to set presets defined by location, name, number, and type on each batch.

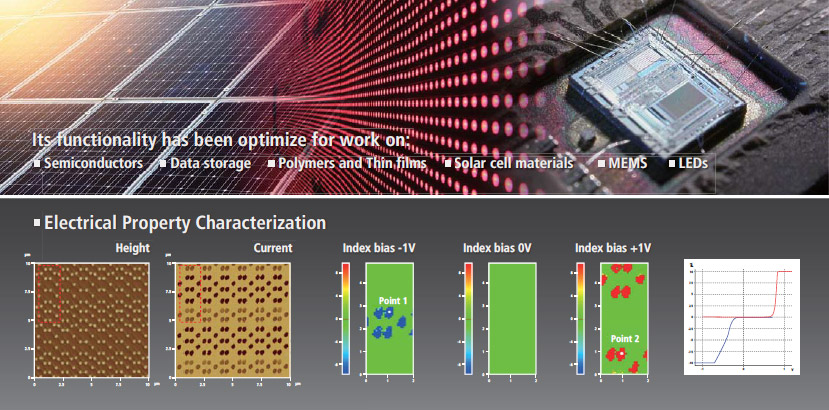

Optimized for a Wide Range of Applications

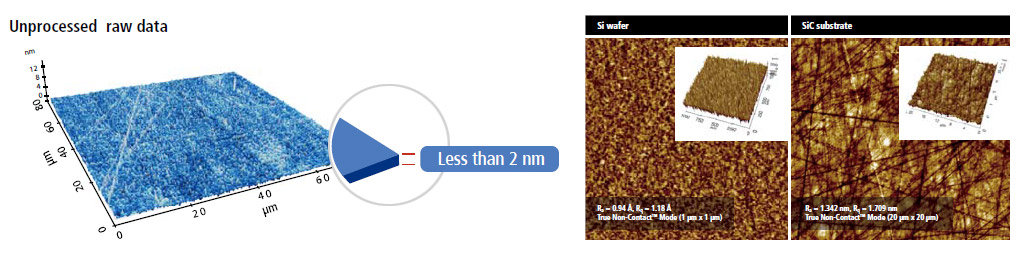

The NX20 300mm provides recipe-automated AFM measurement for numerous applications providing advanced measurements and analysis of samples at the nanoscale. With the ability to measure roughness, height, and depth, perform defect reviews, electrical and magnetic failure analyses, thermal property characterization, and nanomechanical property imaging, the AFM is ideally suited to a wide range of tasks performed by FA, QA, and QC engineers that work with large samples.

Atomic Force Microscope Surface Analysis & Morphology