Description

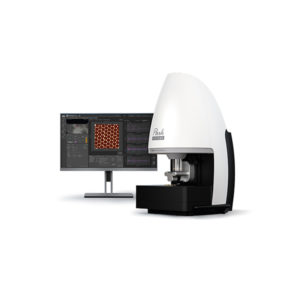

The Thermo Scientific™ SEM is a highly flexible scanning electron microscope (SEM) capable of remarkable all-around performance under a variety of

conditions. With its low vacuum and environmental SEM (ESEM) modes, it is fully equipped to analyze charging, outgassing or otherwise difficult samples.

Highlights

• Easy and quick sample loading for multiple and/or heavy samples

• Simplified sample navigation with the Thermo ScientificTM Nav-Cam™ Camera and navigation montage

• Ease of use thanks to User Guidance and an Undo function

• Excellent image quality with advanced scanning modes and beam deceleration

• Intuitive elemental analysis with Thermo ScientificTM ColorSEM™ Technology

• Compatible with a wide range of samples thanks to dedicated vacuum modes

• Ability to image materials in their natural state with the unique environmental mode

• Easily controlled dynamic experiments with integrated heating/cooling stages

• Wide selection of detectors and accessories including scanning transmission electron microscopy (STEM), cathodoluminescence, scripting, as well as image tiling and stitching

Process control using electron microscopy

Modern industry demands high throughput with superior quality, a balance that is maintained through robust process control. SEM and TEM tools with dedicated automation software provide rapid, multi-scale information for process monitoring and improvement.

Quality control and failure analysis

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

Semiconductor Pathfinding and Development

Advanced electron microscopy, focused ion beam, and associated analytical techniques for identifying viable solutions and design methods for the fabrication of high-performance semiconductor devices.

Yield Ramp and Metrology

We offer advanced analytical capabilities for defect analysis, metrology, and process control, designed to help increase productivity and improve yield across a range of semiconductor applications and devices.

Semiconductor Failure Analysis

Increasingly complex semiconductor device structures result in more places for failure-inducing defects to hide. Our next-generation workflows help you localize and characterize subtle electrical issues that affect yield, performance, and reliability.

Physical and Chemical Characterization

Ongoing consumer demand drives the creation of smaller, faster, and cheaper electronic devices. Their production relies on high-productivity instruments and workflows that image, analyze, and characterize a broad range of semiconductor and display devices.

FEI Microscopic Solution