Description

Unique Capabilities

PHI’s scanning XPS microprobe instrument platform provides secondary electron images (SXI) generated by scanning a focused 10 μm x-ray beam across the sample.

These SXI images have a contrast mechanism that is dominated by photoelectron yield (composition), and therefore often reveal features that are not visible

optically or related to topography. SXI images provide a high degree of confidence in locating small features for analysis. The micro-focused x-ray beam defines the analysis area

pattern for large area spectroscopy, micro area spectroscopy, chemical state imaging, and depth profiling.

Microprobe Workflow

A x-ray beam induced secondary electron image immediately revealed the presence of unexpected localized contaminants on a polymers surface. Micro

area spectra obtained with a 20 μm diameter x-ray beam identified a fluorocarbon contaminant in a few minutes. Elemental maps show the smaller features in

the secondary electron image do not contain fluorine. A micro area spectrum from the smaller features, obtained using a 10 μm diameter x-ray beam, identifies

the presence of a second contaminant that contains Zn.

High Productivity

Whether you are analyzing a thin polymer sheet, a large plastic lens, a steel razor blade, or electrically isolated solder bumps; the instrument set-up is the same. Point

and click at an optical image to select the analysis areas. Then start the analysis with the dual beam neutralizer and the auto-Z functions activated to provide automatic

sample alignment and charge neutralization. There is no individual sample tuning, no concerns over sample composition and size, and no worries about walking

away from the instrument and letting it automatically collect data from all your samples.

Optimized Configuration

A focused x-ray beam, high sensitivity spectrometer, high performance floating column ion gun, turnkey dual beam charge neutralization, compucentric Zalar rotation, and

advanced data reduction algorithms provide the highest performance XPS depth profiling capability available. Applications include: semiconductor thin film structures,

magnetic media thin films, optical coatings, decorative coatings, wear coatings and, with the optional C60 or GCIB cluster ion beams, polymer and organic thin films

such as time release drug coatings and organic LED films.

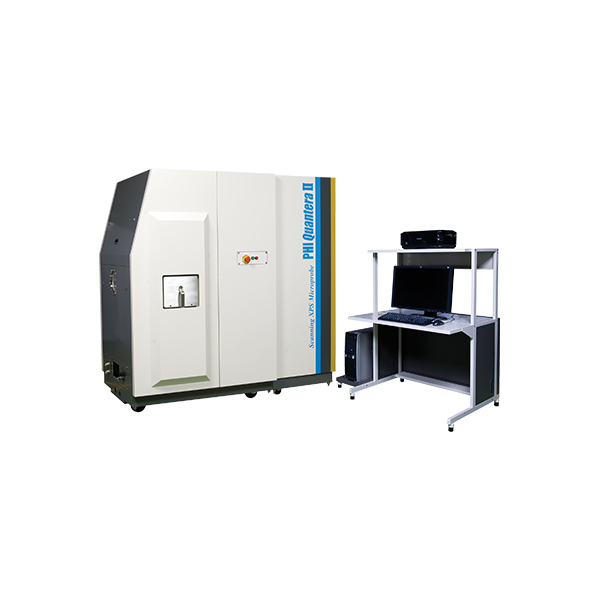

PHI Quantera II Scanning XPS Microprobe